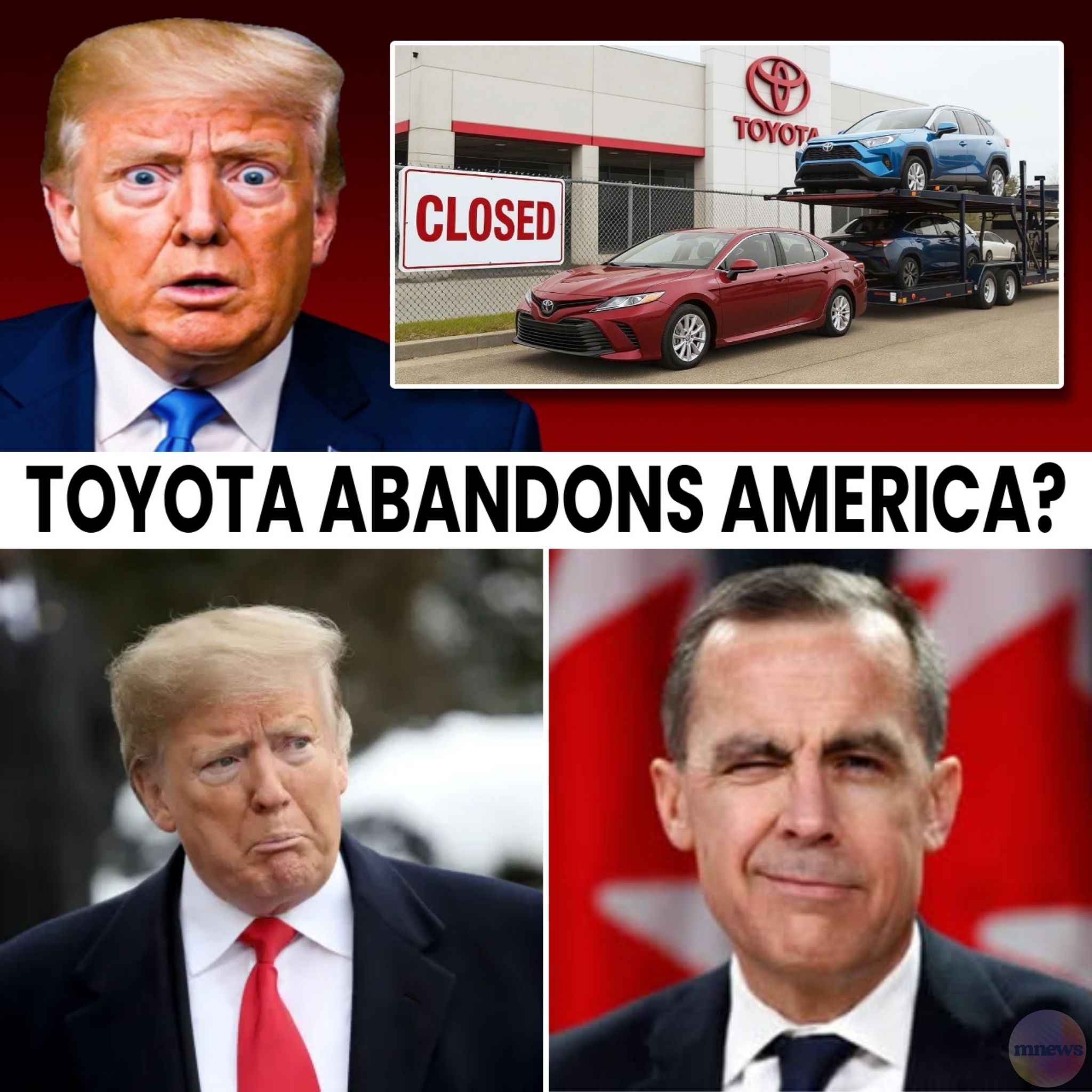

In a dramatic turn of events, the U.S. automotive industry finds itself grappling with self-inflicted wounds as tariffs designed to bolster domestic manufacturing have instead catalyzed a shift in production to Canada. Toyota’s new $14 billion battery plant in Greensboro, North Carolina, is set to begin operations, but the excitement is overshadowed by a troubling trend: the decline of U.S. auto production and the rise of Canada as a manufacturing powerhouse.

Once a symbol of American industrial strength, the auto sector is now experiencing a crisis of confidence. In Kentucky, where Toyota’s assembly lines have long defined community life, production has slowed significantly. Lexus and RAV4 lines have been halted or scaled back, leaving workers and surrounding towns feeling the strain. This downturn is not merely a temporary setback; it signals a potential redefinition of North American manufacturing.

The root cause of this turmoil lies in the White House’s recent implementation of a 25% tariff on imported vehicles and components. Intended to protect domestic jobs, this policy has backfired spectacularly, with automakers absorbing nearly $18 billion in added costs in just one year. Production has plummeted by over 20,000 vehicles per day, prompting international manufacturers like Volvo and Hyundai to scale back U.S. operations or relocate elsewhere.

In stark contrast, Canada has positioned itself as a beacon of stability and opportunity. With a clear industrial strategy and an emphasis on clean energy, Ottawa has attracted significant investments from global automakers. Honda’s $15 billion investment in Ontario and Toyota’s expansion in Canada highlight a growing trend: manufacturers are increasingly favoring Canada’s favorable business environment over the U.S.’s rising protectionism.

The implications are profound. Japanese automakers now produce nearly half of all vehicles in Canada, with Toyota alone contributing around 500,000 units annually. As the U.S. faces rising costs and diminished production capabilities, Canada is strengthening its role in the global auto market. The clean energy grid in Canada has reduced production costs by an estimated 20% compared to American plants, making it an attractive option for manufacturers seeking efficiency and sustainability.

As the U.S. struggles under the weight of its own tariffs, the automotive landscape is shifting. Major players like Ford and GM have already reduced outputs, and auto haulers are reporting the weakest shipment levels in over 15 years. The ripple effects of these tariffs are felt across the supply chain, affecting steel workers, parts manufacturers, and logistics hubs nationwide.

The question now looms: will the U.S. adapt to this new reality, or continue down a path that risks further weakening its industrial base? As Canada secures its position, the U.S. must confront the urgent need for a coherent industrial strategy that fosters growth rather than constriction. The next decade will be pivotal, as the balance of economic power in North America hangs in the balance, with Canada poised to emerge as the new manufacturing leader. The time for decisive action is now, as the consequences of inaction could reshape the industry for generations to come.